How to avoid the risks of floating photovoltaic system projects?

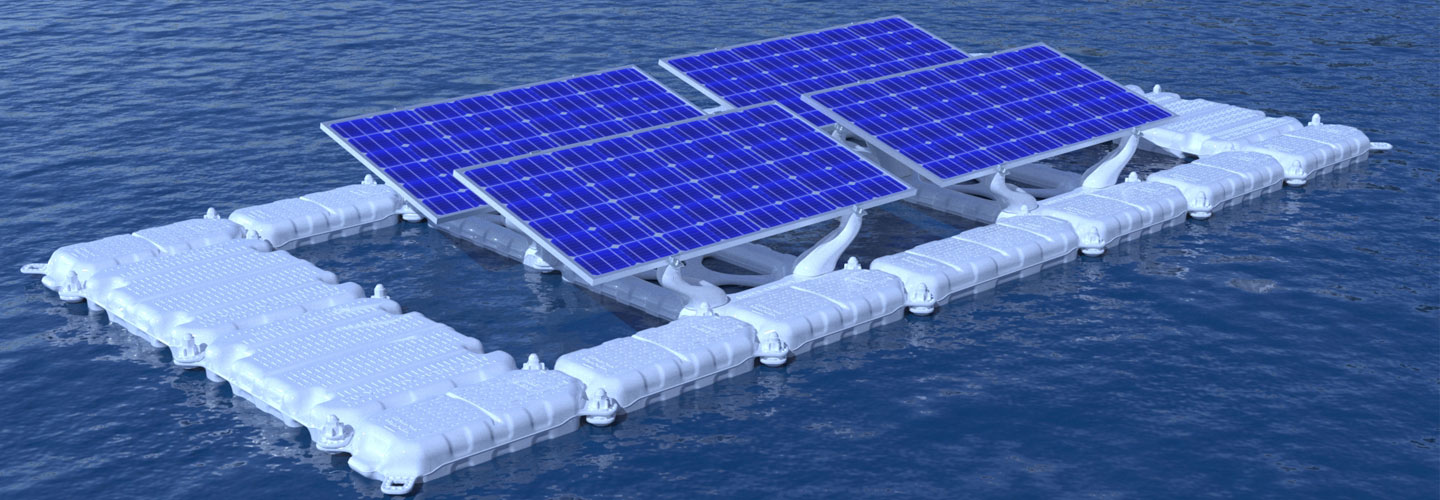

Floating

photovoltaic power plants have spread all over the world. There are

nearly 800 surface photovoltaic power plants in operation and under

construction. The cumulative global application has exceeded 1.1GW,

involving multiple application scenarios such as drinking water

reservoirs, hydroelectric power station reservoirs, offshore waters and

extreme cold areas. , Reliability and environmental protection have been

widely recognized.

How to avoid the risks of floating

photovoltaic system projects has become a focus of the industry. We have

summarized the following three points. If these three points are well

done, project risks can be greatly reduced.

1. Product design is the source

The

most basic components of the floating array are floating bodies,

brackets, bolts and nuts for water surface photovoltaics. Product

design, material selection, processing technology, product testing, etc.

not only affect the strength, toughness, environmental protection,

weather resistance, and service life of the product itself, but are also

basic factors that determine the stability and safety of the floating

power station. Using low-end inferior materials and cutting corners to

reduce the wall thickness of the floating body will greatly reduce the

service life of the system and bring project risks. In addition to

adequate project site exploration and strict simulation calculations, a

large number of experimental verifications and large-scale actual

project operation verifications are also indispensable.

2. The anchoring system design is the key

The

role of the anchoring system is to fix the floating array, respond to

rising and falling water levels, resist strong winds and waves and water

flow, control the displacement range of the floating array, and ensure

the safe and stable operation of the surface photovoltaic power station.

The design of anchoring system needs to comprehensively consider key

environmental factors such as local wind load, water depth and drop,

water size, topography, etc. It needs to pass "theory + experiment"

analysis and accumulate multiple project implementation experience to

ensure safety.

3. After-sales technical guidance is a guarantee

Rich

experience in large-scale project installation and construction

guidance, professional after-sales technical team, scientific

construction platform construction suggestions, and sub-square temporary

anchoring schemes and other technical guidance guarantees play an

important role in the smooth implementation of the entire project, and

can reduce the risk of construction To the lowest. Construction

technical guidance is very important to the progress of the project, but

a very small number of manufacturers have insufficient after-sales

technical guidance and have not fulfilled their responsibilities and

obligations.

In order to reduce the project risk as much as

possible, the supplier needs to provide specific construction platform

design suggestions according to different project terrain

characteristics, matching the site terrain conditions and construction

schedule requirements.

Xiamen Mibet New Energy Co., Ltd.

is a high-tech enterprise with advanced patented technology and

efficient services. It specializes in the research and development,

manufacturing and sales of solar energy products, and is committed to

providing the most reliable and economical solar photovoltaic mounting

system solutions. Since the establishment of the company, solar products

have been sold to more than 100 countries and regions, becoming one of

the largest exporters of solar photovoltaic products.

评论

发表评论